Special Solutions & BY Treatment

BY Treatment

BY treatment is the controlled cooling of forged/rolled parts from the forming heat. The main objective is to achieve a uniform and defined microstructure that meets the criteria for solidity and/or optimum machinability under series production conditions.BY treatment is primarily used for swage and ring-rolled parts in car and commercial vehicle construction for gearboxes and axles. It can also be used for the special heat treatment of small castings. It also replaces conventional heat treatment processes such as tempering, normalizing and BG annealing.

Foundry Industry

For the foundry industry, in particular for the production of ductile cast iron pipes, we offer pipe annealing furnaces for pipes DN80 to DN2600 as well as low-temperature systems for subsequent pipe coatings such as polymer, epoxy, polyurethane and concrete.Investment Casting Technology

In investment casting technology, we help you to reach your high dimensional accuracy goals with wax burnout furnaces. Here we ensure that all wax residues are completely burnt.Special Solutions

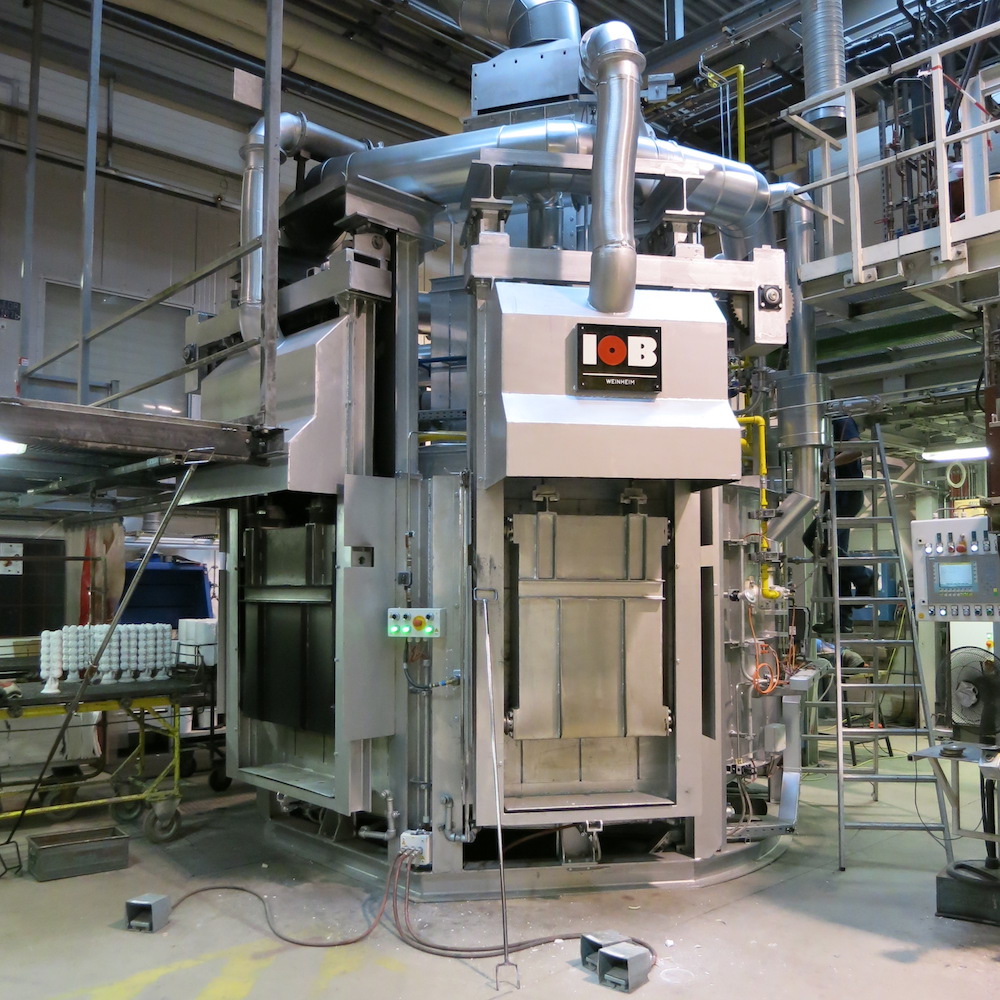

Our special solutions include highly efficient tip-up furnaces as well as powerful, indirectly heated hood furnaces and hood-type bogie hearth furnaces. We can also supply you with high-precision belt furnaces and roller hearth furnaces, which are mainly used in large-scale production.

Special hood furnace