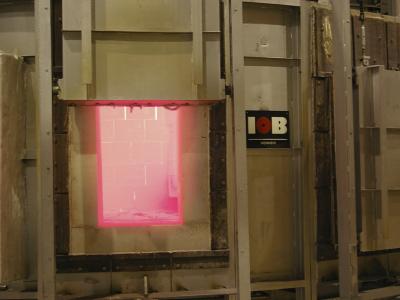

Heat-Resistant Special Steel Castings

By combining state-of-the-art design and production technologies with over 50 years of experience in industrial furnace construction, we guarantee our customers quality, reliability and flexibility in cast steel products. Our first-class castings are tailored to individual applications.

Casting is the most effective and fastest way to produce complex shapes in steel. Especially when it comes to producing components in special alloys with increased physical and mechanical properties, casting is the appropriate and only choice.

We offer you high-quality castings for these applications that meet your specific needs. The available steel grades and specifications can be found in this document (download PDF, engl., 67 KB).

Casting is the most effective and fastest way to produce complex shapes in steel. Especially when it comes to producing components in special alloys with increased physical and mechanical properties, casting is the appropriate and only choice.

We offer you high-quality castings for these applications that meet your specific needs. The available steel grades and specifications can be found in this document (download PDF, engl., 67 KB).

Advantages of casting over other manufacturing processes:

- Flexibility in Project planning.

- The production of complex shapes.

- Versatility through the use of different alloys.

- Robustness due to the increased mechanical properties of the alloys.

- Quality due to the higher uniformity of the mechanical properties of components

- Low cost due to the long service life of the product.

The main areas of application for steel castings are:

- the steel industry,

- the forging industry,

- heat treatment,

- petrochemical industry,

- aerospace industry,

- environmental technology,

- the energy sectors and

- the waste management plants.